Do you want to know the secret to increasing profits while maintaining top-notch quality as a signmaker? The tools we use at our sign shop can make or break the efficiency of our business. There are so many things that equate to how much profit we are making from a project; this includes material cost, labor and machine time.

When it comes to cutting metal signage, the common tool that often comes to mind is a CNC router. A popular device, no doubt, but what many sign makers may overlook is the economic and superiorly effective alternative, which is laser cutting.

Signmakers are constantly looking for better, cleaner, more accurate, and more affordable methods that enhance productivity and profitability in the way they do their signs for their customers.

If you yourself are a Signmaker, you’ll want to read through this article in its entirety as we break down the juxtaposition of CNC Router engraving and laser cutting as they pertain to aluminum cutting for metallic signs.

Let’s get started!

Advantages of Laser Cutting

Laser cutting, as opposed to traditional CNC router cutting, carries a whole host of advantages that, when compared side-by-side, make it the clear winner. Let’s look at those advantages now.

Reduced Material Costs

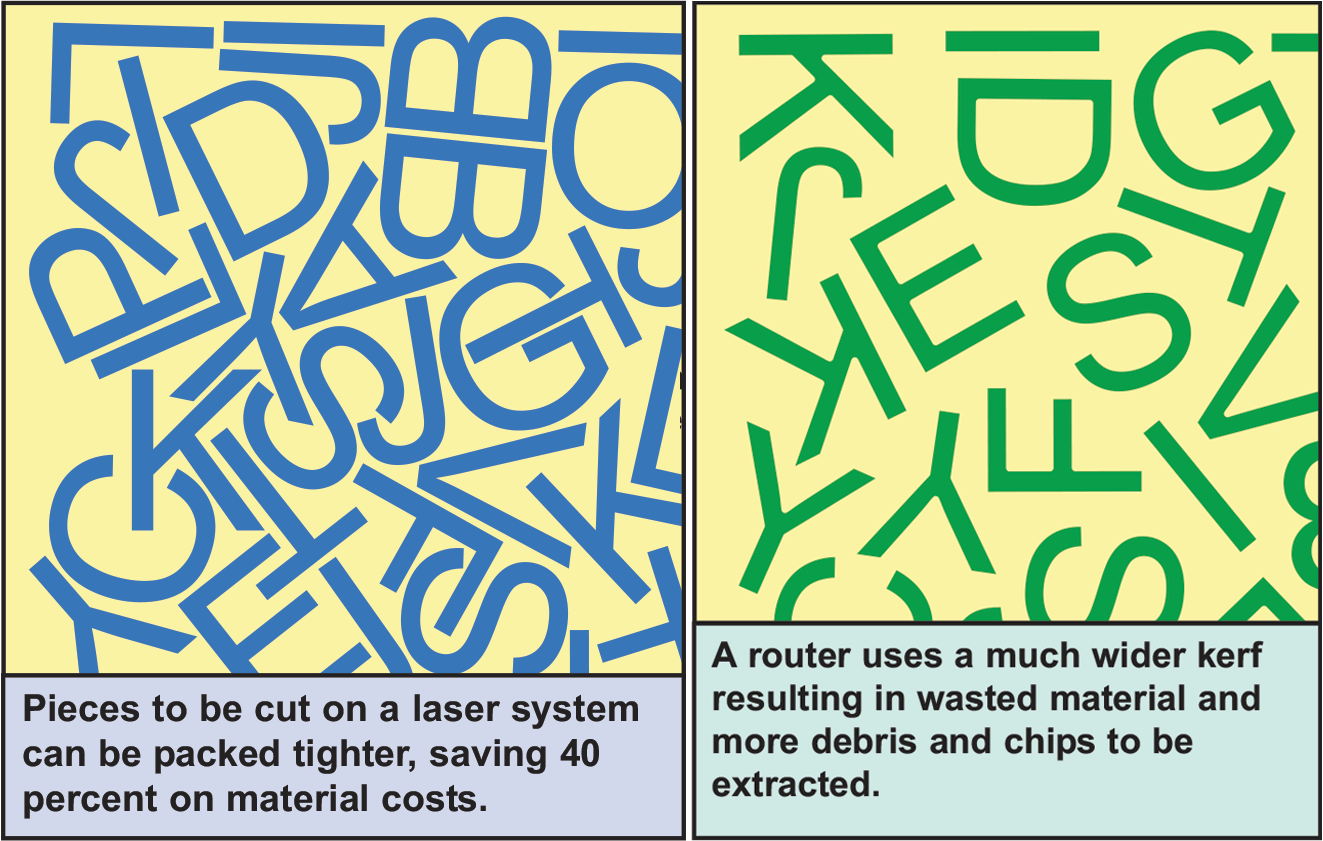

One of the standout features of laser cutting is its ability to reduce material wastage.

For instance, when cutting 6" tall aluminum letters, a laser uses about half the material required by a CNC router. This not only cuts down the material cost by nearly 50% but also reduces the environmental footprint of production. The lower material requirements are due to the laser’s ability to cut with greater precision and smaller kerf widths compared to routers.

Lower Labor Requirements

Laser systems significantly streamline the manufacturing process. The automation and precision of laser technology minimize the need for manual adjustments and corrections, which are often necessary with CNC routers.

From file preparation to the actual cutting, laser systems can simplify operations, thereby reducing labor costs and allowing employees to concentrate on other productive tasks.

Increased Production Speed

The operational speed of laser cutting machines is a major advantage. These machines can complete tasks much faster than CNC routers.

For example, a job that takes a CNC router approximately 1.5 hours can be completed in about 20 minutes with a laser cutter. This speed enhancement not only boosts a company's production capacity but also allows for more orders to be processed in the same amount of time, significantly increasing potential revenue.

While it might be a more costly upfront equipment cost, it will quickly pay for itself, given the amount of increased productivity and speed it can render.

Detailed Cost Comparison

Let’s consider the real-life scenario of one of our customers, a sign company, tasked with producing a set of 12 aluminum letters, each 6" tall and ¼" thick, using both a CNC router and a laser for comparison.

Here’s how the costs and processes differed:

Using a CNC Router:

● Material and setup: The router requires about 4.4 square feet of aluminum, costing approximately $61, with additional tooling costs of $30.

● Labor and machine time: Preparing and cleaning the files, nesting, and physical cutting require about 3 hours of labor ($105) and 1.5 hours of machine time ($90).

● Total Cost: The production cost totaled $301 for the set of letters.

Using a Laser:

● Material and setup: The laser cuts the same letters using only 2.3 square feet of aluminum, reducing the material cost to $32.

● Labor and machine time: With streamlined file preparation and reduced cleanup, the process took only 35 minutes of labor ($20) and 20 minutes of machine time ($27).

● Total Cost: The total production cost using a laser amounted to just $94 for the same set of letters.

See the difference?

The Laser cutting process dramatically reduced labor, machine time, and material costs, resulting in an overall cost savings from start to finish!

Last Comments on Laser Cutting as an Alternative to CNC Routers

Switching from CNC routers to laser cutting systems is a strategic move for Signmakers aiming to optimize their production processes. It’s the next-gen solution for any Signmaker business looking for ways to save on process costs, scale their business, and win more business. Not to mention, it also creates a really solid impression when customers learn you’re using cutting-edge tech (no pun intended) in your process. It can increase their trust in your brand and lead to a happier customer experience overall.